Construction, Maintenance & Renewal Machines

Transformative solutions to a sustainable future

Modern rail networks demand advanced technologies to deliver faster, safer, and more sustainable track renewals.

The challenges of traditional high-output methods highlight the need for innovative solutions that deliver quality, reliability and efficiency without compromise.

Unipart is redefining the standard with a range of performance-driven solutions for construction, maintenance and renewal projects. Designed to overcome the limitations of conventional methods, these solutions deliver exceptional safety, speed and adaptability, whilst cutting costs. This is the future of rail efficiency, engineered for global operators.

.png)

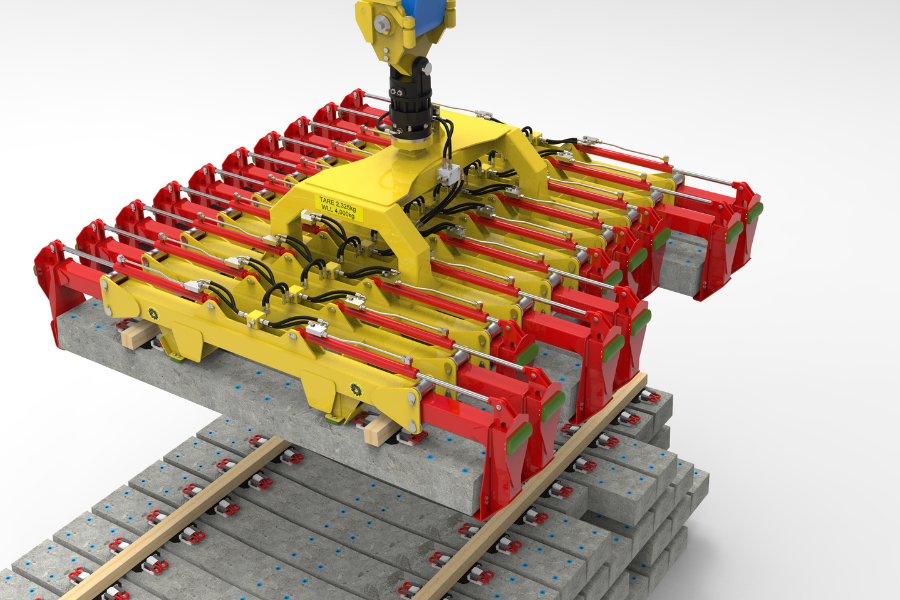

Sleeper Layer

Delivering a new approach to the laying and positioning of sleepers in track construction and renewal projects.

Rail Handler

Our algorithms perform deep analysis, displaying critical information for rapid understanding of asset performance.

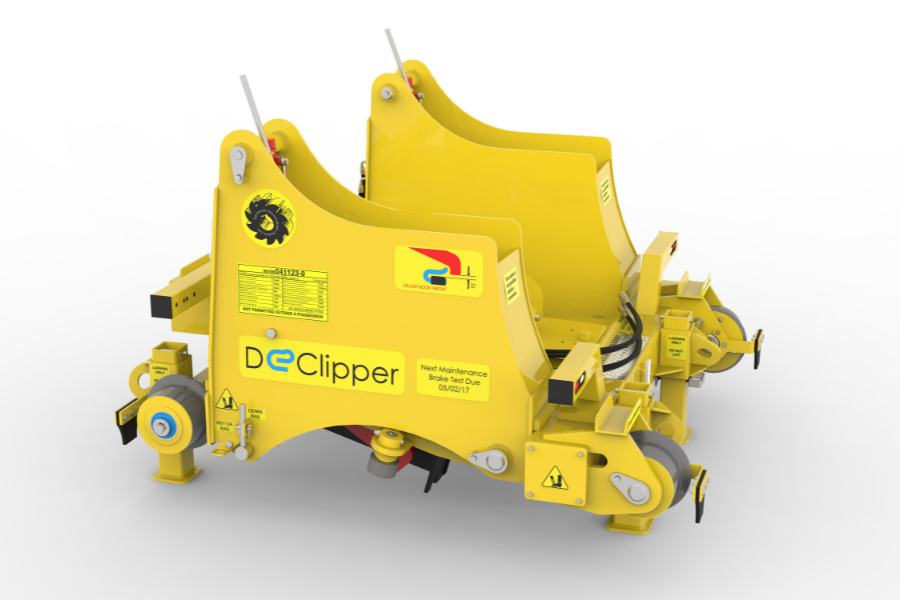

Rail Clipper

Enable detailed analysis to predict potential issues, minimise downtime, and extend asset lifespan.

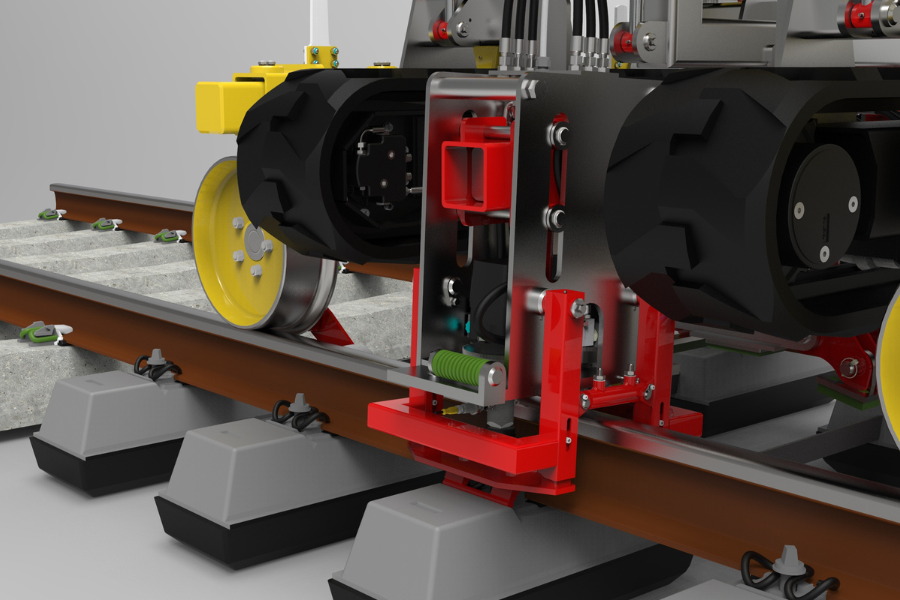

The Sleeper Layer delivers a new approach to the laying and positioning of sleepers in track construction and renewal projects.

Self-propelled and semi-autonomous in operation, this unique machine offers high output and high precision, requiring only 1 operator and precisely delivering up to 1000 sleepers per hour, onto the track bed.

The sleeper spacing is controlled by a shaft encoder on a wheel running on the track centre line, which can be adjusted to any desired setting via a touch-screen control panel.

The machine is powered by a 55kW JCB diesel engine built to the latest emissions specifications. The plc control maximises efficiency by monitoring the engine parameters and hydraulic system performance, minimising fuel use.

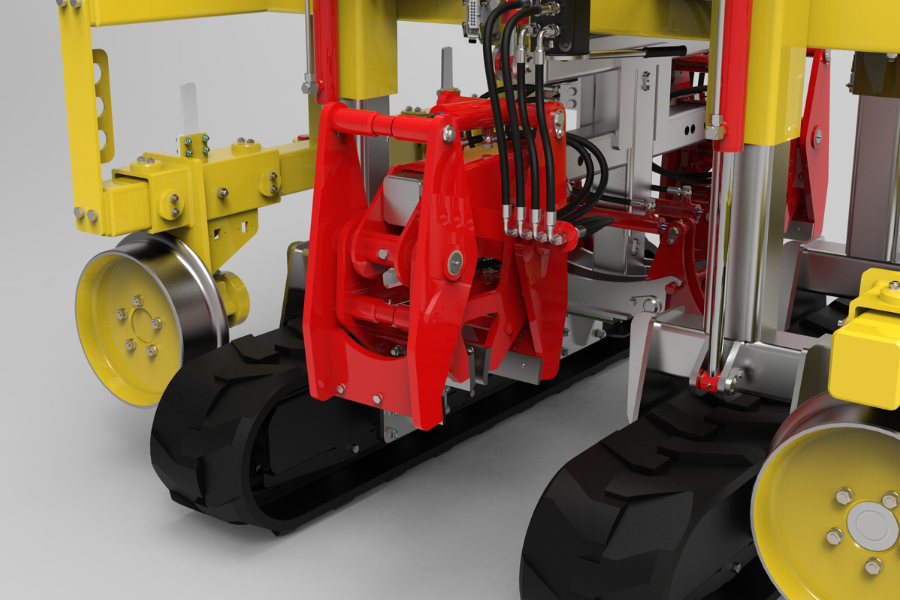

The Rail Handler delivers an innovative approach to the moving, transposing, and positioning of rail.

This powerful and versatile machine offers a variety of applications and benefits for rail maintenance teams, including lifting and transporting rails, and threading long welded rails.

The machine offers the capability to install, remove, transpose or replace rails quickly and safely, even under live overhead catenary power lines.

The Rail Handler can also be used for a variety of other applications including repadding, clearing ballast, and providing power for Hydraulic tools. As the Machine uses attachments, it can also be tailored to meet other project requirements increasing the utilisation and adaptability of the machine.

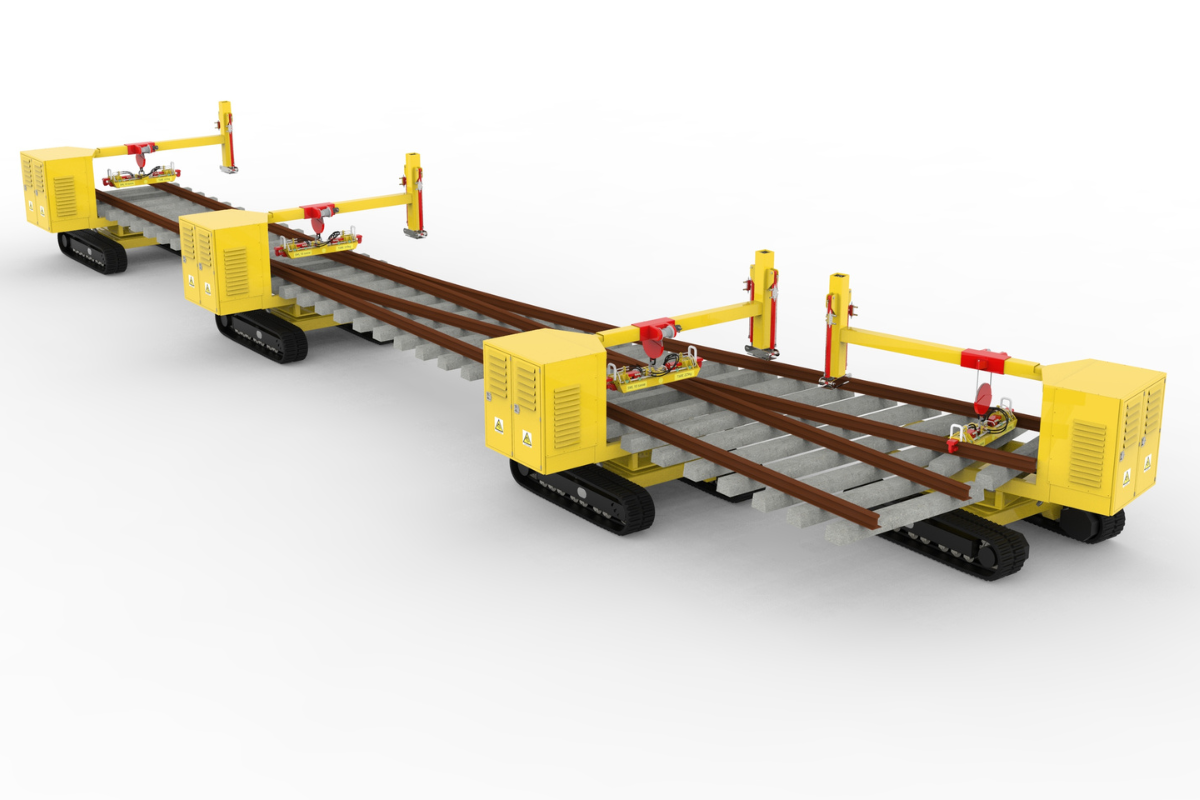

Provides clipping and de-clipping of rail fastening solutions in a safe, efficient, and fast manner.

The powerful rubber tracks make this machine capable of loading and unloading itself onto delivery vehicles and to move on and off the rails, without need for a crane. Once on the rails, the machine can lift sleepers in track renewals work, as well as either setting or releasing the clips, all at high speed as a result of the semi-autonomous mode.

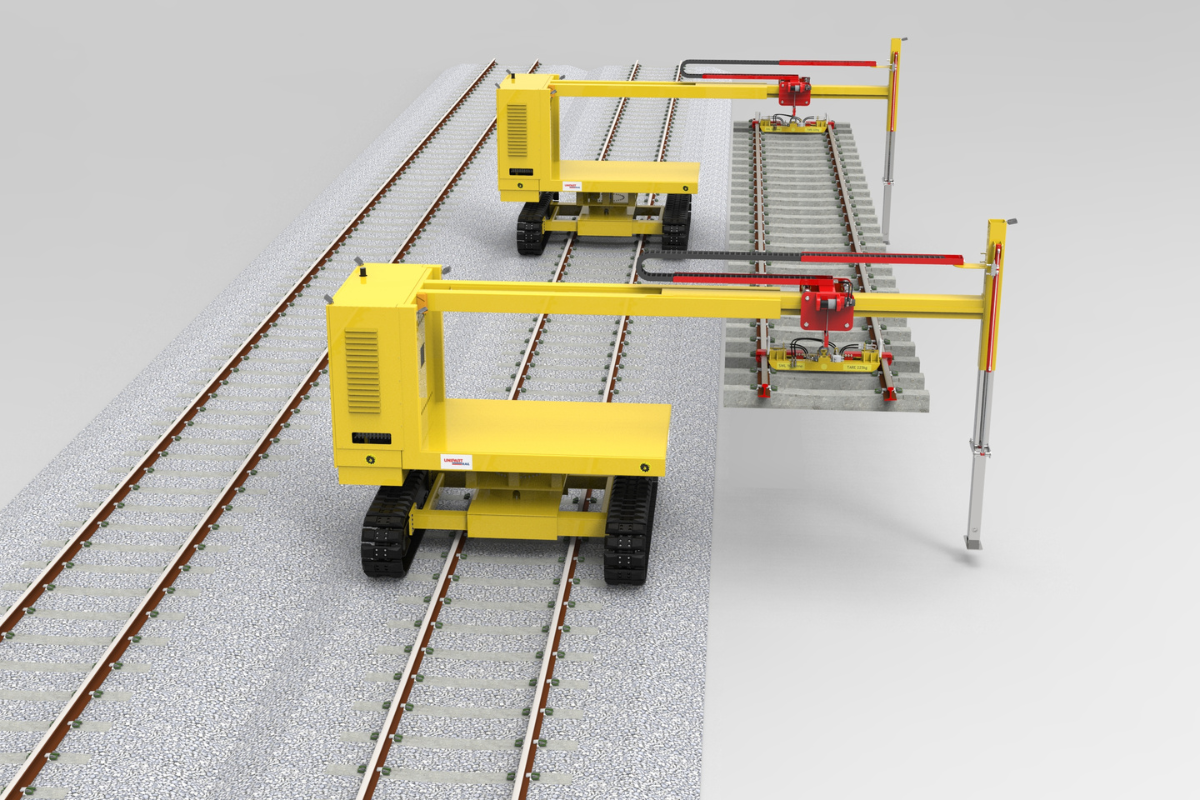

A transformative solution for global panel handling.

MoRPH (Mobile Rail Panel Handler), is a new machine designed to disrupt the current track renewal and maintenance supply chain by providing all of the functionality of specialist plant hire equipment, at a much lower cost and increasing the availability of handling machinery, allowing major renewals work to be delivered on much shorter timescales.

With the ability to handle both plain line and S+C track panels, this unique machine provides the capabilities of a tracked gantry crane system, whilst eliminating the risk to adjacent track infrastructure and components. MoRPH offers higher utilisation and better return on investment than any other machine on the market.

Rail and track attachments

Innovative solutions and equipment for global railway construction, maintenance and repair projects.

.png)

Reduce Fuel and CO2 consumption

Install FuelActive to deliver 92% cleaner fuel to engines and save up to 5% in fuel and CO2.

Full plant and machinery range

Accelerating project delivery with transformative global plant & machinery solutions.

.png)

.png)